Call Us Toll Free+1 114-121-1239

Corrugated packaging is more than just cardboard. It helps to support global trade every day. Many businesses trust it because of its durability, flexibility, and cost-effectiveness. From shipping food deliveries to heavy items, it protects products at every stage.

When people think of corrugated packaging, they usually assume it is just cardboard.

But there's much more to it than that. Cardboard is one kind of material. However, corrugated cardboard is another option. They may look alike, but they are not the same. Each has a specific purpose, depending on the product and its use.

A corrugated box is a container composed of corrugated cardboard. Corrugated boxes are commonly used to transport large or heavy items due to their strength and durability.

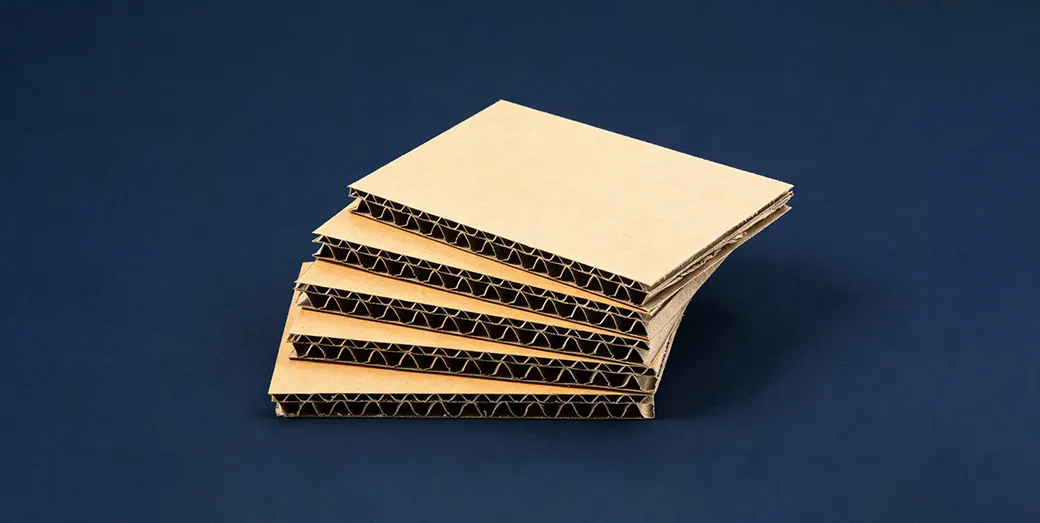

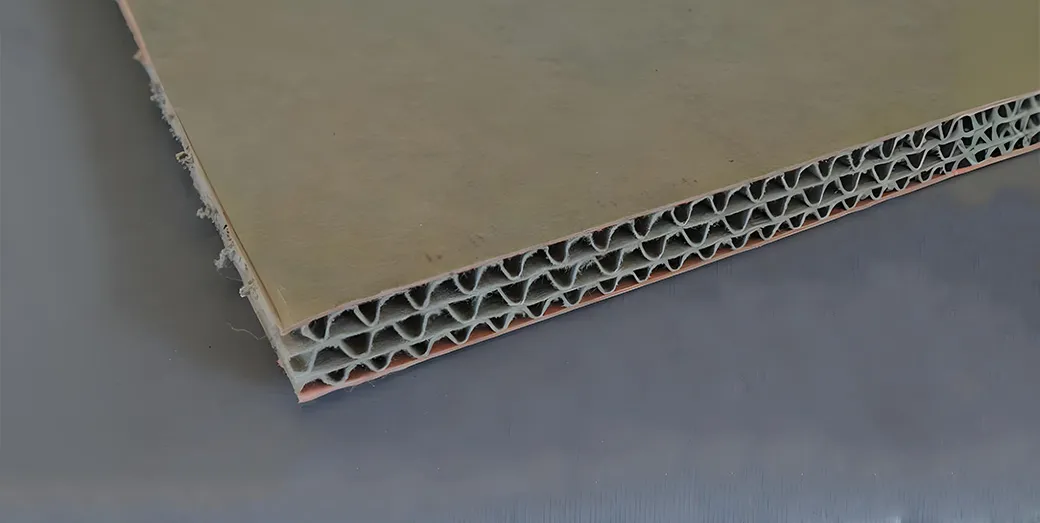

Corrugated cardboard boxes consist of three layers. There is an inner layer and a middle layer.

And there is an outer layer. The center layer is a fragile, wavy sheet of paper known as fluting. The inner and outer layers are thick paperboard, often known as linerboard. The fluting is what gives the box strength. It increases durability. It protects the product inside. This innovative design protects the products during handling and shipping.

Corrugated packaging is typically made from Kraft paper. This can be made from virgin pulp or recycled materials. The two outer liners provide a printed base and moisture resistance. The inner corrugated paper layer gives stress absorption.

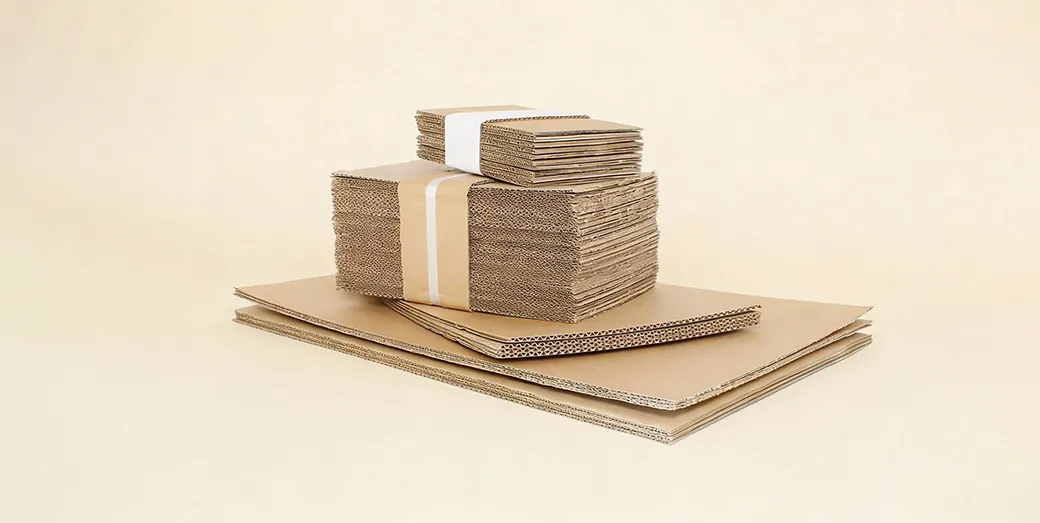

Corrugated cardboard boxes are made from a thick paper core and linerboard. The middle layer is the wavy substance spotted between the linerboard layers, both of which are composed of containerboard. The quantity of medium and linerboard layers determines the strength of corrugated boxes.

Single-face corrugated boards consist of a single medium-fluted layer attached to a single flat linerboard. This basic structure provides lightweight protection and flexibility. Single-face corrugated is ideal for light packaging needs, such as coffee cup carriers, phone boxes, and protective liners. It offers cushioning and surface support, making it perfect for delicate items that don't require heavy-duty protection.

Single Wall Corrugated features one fluted layer sandwiched between two flat linerboards. This structure balances strength and weight, making it the most commonly used corrugated type for shipping and retail packaging. Single-wall corrugated is ideal for everyday packaging needs, including boxes for consumer electronics, small appliances, and e-commerce shipments. It protects products from light impacts while remaining cost-effective and recyclable.

Double Wall Corrugated consists of two fluted layers separated by three linerboards, creating a sturdier and more rigid structure. This type of board is suitable for heavy or fragile items, long-term storage, and warehouse shipments. Double-wall corrugated provides enhanced strength, durability, and stacking support, making it ideal for products such as furniture and large appliances, as well as for bulk shipments that require additional protection during transit.

Triple Wall Corrugated features three fluted layers sandwiched between four linerboards, making it the heaviest and most durable corrugated option. This type is designed for extra-large, heavy-duty shipments, including industrial equipment, compressors, and high-value machinery. Triple-wall corrugated offers maximum protection against crushing, impact, and moisture, ensuring the safety of expensive and sensitive items throughout storage and shipping.

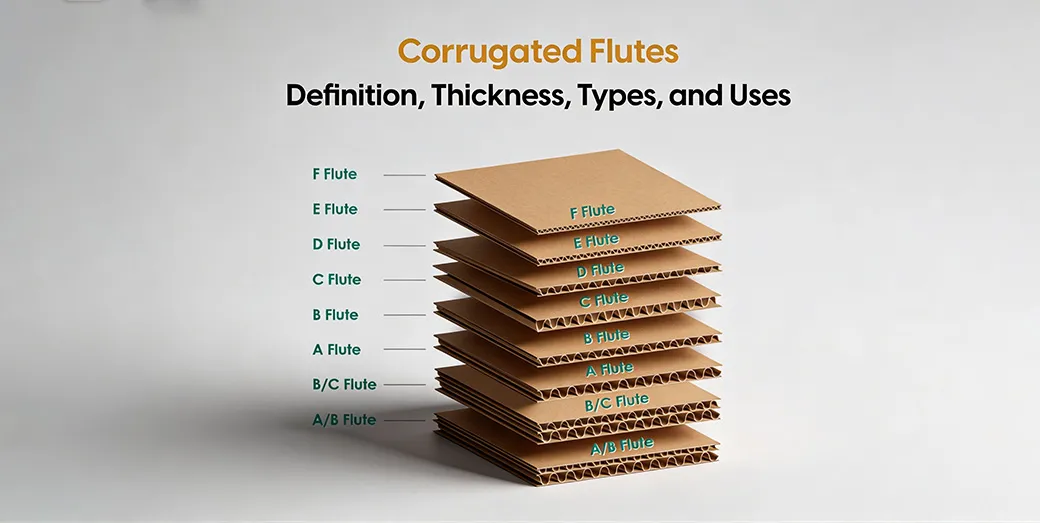

Corrugated flutes provide strength, support, and resistance to breakage. Different flute forms offer more customization options for your package. The flute, also known as a corrugation. It is the wavy, C-shaped layer that separates two sheets of paperboard. It enhances the durability of your corrugated boxes. Flute size dictates the box's thickness and stackability. It can be identified by letter and calculated based on the number of waves per foot.

The most popular flute sizes are:

The most well-known flute is the A-Flute. It has 33 flutes per linear foot and is 1/4 inch thick. Because of the material's thickness, it is protective and ideal for fragile goods. Also, this flute grade offers the best protection and cushioning.

The B-flute has 47 flutes per linear foot and is 1/8 inch thick. As it is much lighter than A-flutes, it maintains its strength. It is typically used for canned goods and counter displays. It is also commonly used to create die-cut designs.

It contains 39 flutes per linear foot and is 3/16 inch thick. You may be aware of the most popular option for shipping boxes. It is widely known and commonly chosen.

1/16" thick is not commonly used in shipping. E-flute thickness is on the thinner end of flute grades. Therefore, it is a substitute for paperboard folding cartons. You may still use E-Flute for cosmetics, sensitive glass, ceramics, and other tiny and delicate items. E-Flute offers great compressive strength, crush resistance, and a reasonably flat surface. This will make it ideal for high-quality printing applications.

The following are the different types of corrugated box styles for premium packaging in detail:

Slotted corrugated boxes are one of the most popular and adaptable box styles.

They are sturdy, adaptable, sustainable, and cost-effective. These boxes are created from a single sheet of corrugated cardboard. The sheet is scored to generate fold lines, then slots to create the top and bottom flaps. Box styles vary according to flap size (RSC, FOL, OSC, etc.).

Telescope boxes are formed of corrugated board and can have one, two, or three walls.

They consist of two parts: a base and a cover that goes over it, much like a shoebox.

Both sections are cut, slotted, and folded to create sturdy walls, with bonded corners for more strength. These boxes are ideal for stacking, delivering heavy goods, and preserving fragile products.

Rigid boxes, sometimes known as bliss boxes. It consists of three parts: two flat end panels and one long body portion. The body folds to create the sides and bottom, and everything is bonded together for strength. The result is a robust six-sided box with high compression strength, perfect for stacking and protecting items.

Self-erecting boxes, also known as auto-lock or crash-lock boxes. They are constructed from single or double-wall boards. When the sides are raised, the base develops automatically. It will help you save time and effort by eliminating the need to fold or glue. They come in square or bespoke forms. Also, they are durable even after many uses. It is ideal for cosmetics, skincare, food, gadgets, and accessories.

Corrugated boxes are used in almost every industry because they are strong, versatile, and cost-effective.

If you've been following along, you may already understand why corrugated packaging is so popular. Here are some major advantages:

Corrugated boxes reduce impacts and cushion goods, ensuring their safety during transportation. Thicker corrugated cardboard is more resistant to damage from heat, moisture, and physical impacts during transit. Also, ensuring that items arrive in good shape.

Corrugated cardboard is an eco- friendly packaging choice because it is made from recycled fibers.

Customizable: You may easily change the size, thickness, shape, and printing to create packaging that perfectly fits your brand.

These corrugated boxes are the foundation of the packaging business. They keep products safe during delivery and create memorable unpacking experiences. Whether you're a retailer, a bulk supplier, or a developing e-commerce business, you need to send the correct corrugated box shape. The corrugated flute can provide product safety, consumer trust, and brand value.